SEVEN STAR ENGINEERS FABRICATORS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SEVEN STAR ENGINEERS FABRICATORS

High Speed Heater Cooler Mixer

Perfect height to dia ratio of vassel.

Precise Peripheral speed of mixing tool.

Least down time, so payback period is higher

Unmatched Pneuma seal / Capsule Technology.

Proper design of impeller.

Computerized balancing of rotating parts.

Best quality material of all key components.

Unique design of bottom & discharge valve.

Very prompt after sales services.

Experience of manufacturing highest number of high speed mixers.

High Speed Heater Cooler Mixer With Batch Hopper And Spring Conveyour

Manual or Automatic Operation Option.

Machine of clear construction with easy access for operation and maintenance

Material flow through Flexible HDPE Pipe and spring made from Special Spring Steel Material.

Our all Spring Hopper Loader is equipped with Vibrating Fork in Place of rubber Diaphragm / Proximity.

High Speed Heater Mixer

In a High Speed Mixer, the heat generated due to friction if utilized for mixing, hence it’s known as “High Speed Heater Mixer”. High speed mixers are used to mix solid to solid, liquid and pasty components.

The Seven Star High Speed Heater Cooler Mixer are used in many fields of processing elastomeres or thermoplasts.

The Mixing container is made of stainless steel. It’s interior has industrial mirror finish. By utilization of frictional heat the material may be agglomerated, dried wented or hot colored.

Cooler Mixer

The Hot Mixer should be cooled subsequently in Cooler Mixer. In order to keep it in free flow condition, suitable to storage. Also helps in case of PVC dry blend static free, heat stabilized and stress free compound. Good heat transfer co-efficient, necessary for obtaining short cooling times are essential for high throughput capacities.

One Pack Weighing And Storage System With Screw Feeder

One Pack Storage with Screw Feeder Driven by A.C. Variable Frequency Drive.

Variable (Adjustable) Screw Speed to Control Coarse feed and fine feed to Weighing System.

Minor components can be conveyed from Material Storage Hopper to Weighing Hopper by Screw feeder driven by geared motor

M.O.C. SS 304 (Anti Corrosive) easy to clean and easy to open type design.

Weighing system with 3 Nos. of single ended shear beam type load cell system.

Coarse feed and fine feeding arrangement to achieve maximum possible weighing accuracy.

The system can be interface to the PLC

Small Bag And Jumbo Bag Dumping Station

Provision to feed Small Bag or Jumbo Bag in to Dumping Station.

Aspiration System Incorporated for dust free environment.

Easy to opening of bags with liner / grill protection.

Easy to handling of jumbo bag with hoist / fork lift.

Easy to connect with vacuum conveying system.

Pneumatically operated sack discharge with bag resting hood. Low level probe and emptying flap.

Conical bottom for anti-bridging of feed material.

Lumps Break Screw driven by geared motor is incorporated with Dumping Station.

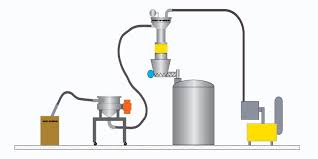

Vacuum Conveying System

Suitable to tranfer up to 3500 Kg / Hr.

Conveying distance up to 40 meters with long radius bends.

Automatic filter cleaning by Reverse Jet Filter Cleaning System.

PTFE Coated antistatic cartridge filters easy to clean.

Compressed air externally provided with timer which keeps the system clean and maintaining the conveying efficiency.

The batch receiving hopper with vibrator for free flowing feeding, level sensors, differential pressure switch, and pneumatically operated actuated butterfly valve

Aspiration System

The Aspiration System can be used in Heater Mixer, Cooler Mixer,Intermediate (Receiving Hopper) & Pressure Conveying System Directly

with Butter Fly Valve.

This Vacuum unit is directly mounted with the system in order to remove

moisture content from PVC Resin as well as from the additives. This system

is designed to extract volatiles and harmful gas of monomer.

During mixing process, the temperature of the product mix gets elevated

Pressure Conveying System With Receiving Hopper Screw Feeder And Vibro Siever

This system is used for conveying of Compound from Cooler Mixer to Storage Silo.

Level Probe for High Level and Low Level for switch off the Pressure Conveying System, when material gets empty in Hopper.

PLC operated state of the art electric control panel.

Conveying Distance: as per customized distance.

Least Dusting by latest technology.

State of the art electric control panel.

Storage Silo

Made from SS 304 , MS or Aluminum with storage capacity of 3 M3to 200 M3 with weighing System.

Facilities raw material storage in dust free and static free environment.

Indoor / Outdoor errection possible.

Silo feeding from Jumbo Bag or Smaller Bag can be provided by pressure conveying system.

Multiple processing lines from silo can be provided by Hopper Loder Vacuum Conveying system.

Hopper Loader Vacuum Conveying System

Automatic loading without human intervention and Easy for conveying the Material from Storage Silo or any other material source to the extruder.

Ratio loading can be also possible for 2 different materials in single

unit.

Cost effective central blower and control to cater two or three loaders simultaneously.

Tools free concept for ease of maintenance.

Different Capacity to suit the Extruder.

Least Dusting and complete cleaning of conveying pipe line.

Level Probe for high level is incorporated in the Hopper Loader Vacuum Conveying System, which gets a signal of high level and switch off the Vacuum Blower.

PLC operated state of the art electric control panel.

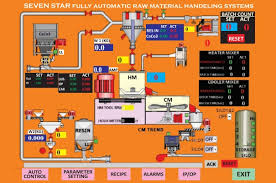

Computerized Plant Automation System

Easy Control on Production, Planning,Supervision and inventory control with process recipe management.

Complete automation, right from the Jumbo bag feeding station to feed multiple processing lines with computerized control

Daily, weekly or monthly reports of total production, raw material consumption or break down can be easily viewed online from any location.

Integrated malfunction message system with option for manual operation

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.